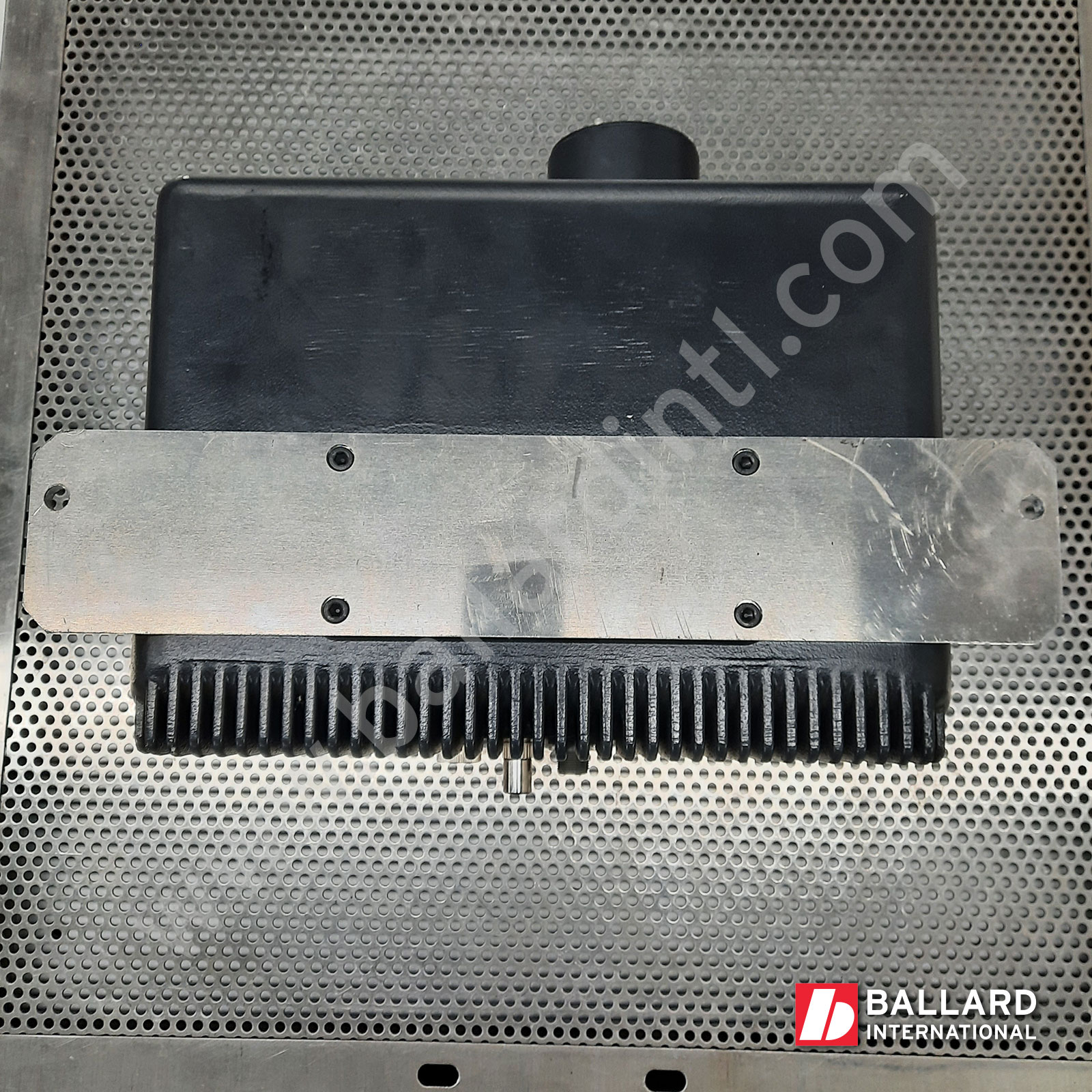

FANUC A05B-1422-B103 iRVision 3D Area Sensor/Projector Unit

SPECIFICATIONS:

- iRVision 3D Area Sensor uses a projector unit for 3D measurements. 3D data is measured in a wide area by projecting structured light very quickly for reliable detection. A 3DA Sensor can be mainly used for depalletizing and bin picking

- 3DA/1300

Different 3D Tools and Functions Available:

- Detection of objects by 3D map (structured light projection) (X, Y, Z, W, P, R).

- 3D Peak Locator Tool: X, Y, Z robot coordinates for non-moving parts. Locally, it finds the highest position in the 3D map.

- 3D Blob Locator Tool: X, Y, Z, W, P, R robot coordinates for non-moving parts. It delivers normal vector of plane positions of the gravity centre of blobs.

- 3D Gripper Finger Locator Tool: Finds the grip position of a work piece using real grippers. In case a part needs to be picked up with a gripper (no vacuum or magnet), additional space around the part is mandatory. GF locator tool uses a gripper model to find the best pick position.

- 3D Box Locator Tool: Finds boxes which are palletized orderly. It uses the size of boxes to find their upper surface by referring to a 3D map and a camera image.

- 3D Cylinder Locator Tool: Finds some cylinder parts from a 3D map.

- 3D One-Sight-Model Locator Tool: Finds a 3D model which has been taught in advance for one face of a workpiece from 3D data and outputs the 3D position and posture.

- 3D COG Measurement Tool: X, Y, Z robot coordinates for non-moving parts. It finds positions of the gravity center relatively to parent GPM or CSM.

- 3D Plane Measurement Tool: X, Y, Z, W, P, R robot coordinates for non-moving parts. This tool is combined with 2D pattern matching and finds the position and orientation of a part.

- 3D Obstruction Measurement Tool: Could be added to GPM or CSM locator tool, to detect higher 3D point and avoid potential collisions before pick operation

- Bin Picking Support: Bin picking system enables the vision system to recognize the position and orientation of all parts, which are randomly placed inside a container. This option contains all mandatory functions required for a successful bin picking application. Bin picking supports all types of iRVision Sensor, and provides two important functions:

– Part list manager organizes all detected parts in accordance to their position and orientation, reachability and other part-relevant information

– Interference avoidance takes all mechanical interference contours in account and plans all mandatory positions for the robot approach, the pick and retract movements. Complete robot movement is planned by the system itself.

Alternate Part No.: IRV-P-3DA1300

$25,536.00 – $42,560.00