FANUC M900iA 260L Robot

FANUC M-900iA 260L Robot

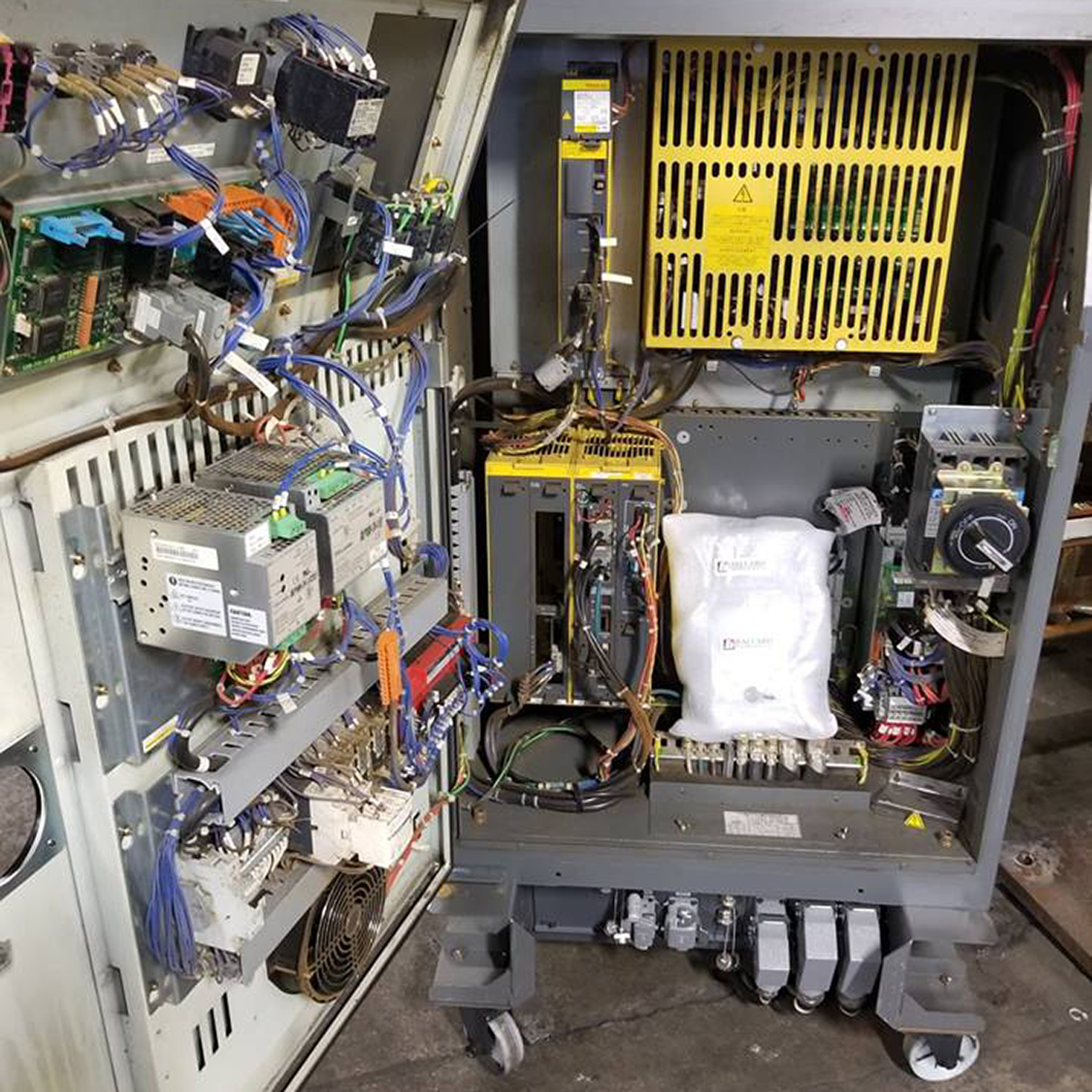

With R30iA Controller

Contact us for availability, shipping options, and pricing.

Fanuc M-900iA is available in the following variations/configurations:

- M-900iA 260L – 260kg Payload

- long reach, 260kg payload, floor, ceiling, or angle mount

- M-900iA 350 – 350kg Payload

- stand reach, 350kg payload, floor, ceiling, or angle mount

- M-900iA 900 – 600kg Payload

- standard reach, 600kg payload, floor mount

SPECIFICATIONS:

- Designed for heavy payload with extended reach

- Software: SpotTool or HandlingTool

- Capacity: 260kg

- Reach: 3100mm

- Power: 480 Volts; 3 Phase; 18 amps

- Robot Weight: 1800kg

- Controller Weight: 380kg

Click here for complete Fanuc M-900iA Specs, including:

– Technical data

– Work envelope

– Mounting requirements/diagram

– End of arm bolt pattern

CONDITION: USED – TESTED, in GOOD WORKING CONDITION